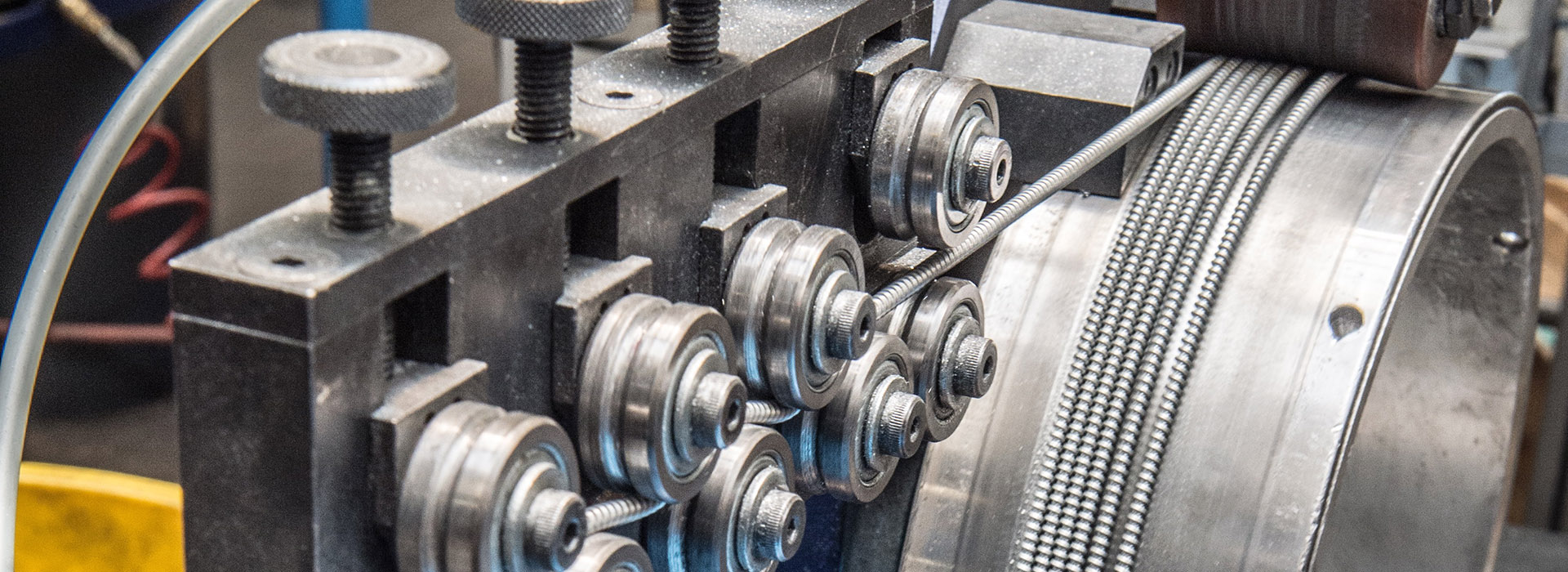

Flexible Shaft Components

Flexible shafts are extremely resilient components that offer a high degree of longevity. They permit continuous work operations even in high-speed ranges (up to 50 000 rpm). They are perfectly suited for substitution of unprotected or complex drive units (angle gearboxes, chain hoists, universal joints, etc).

The following examples indicate a few of the possible uses:

As substitution of unprotected or complex drive units (angle gearboxes, chain hoists, universal joints, etc).

Wherever the power source and the driven part are not properly aligned.

Transmission of mechanical rotary power where a straight connection is not possible.

Connection or driving of components that move relative to each other.

For remotely operating machines in hazardous locations.

For mechanical or manual operation of tools by a remote drive.

To dampen tool vibrations or shocks from the drive unit.

To reduce weight for handheld tools and similar equipment

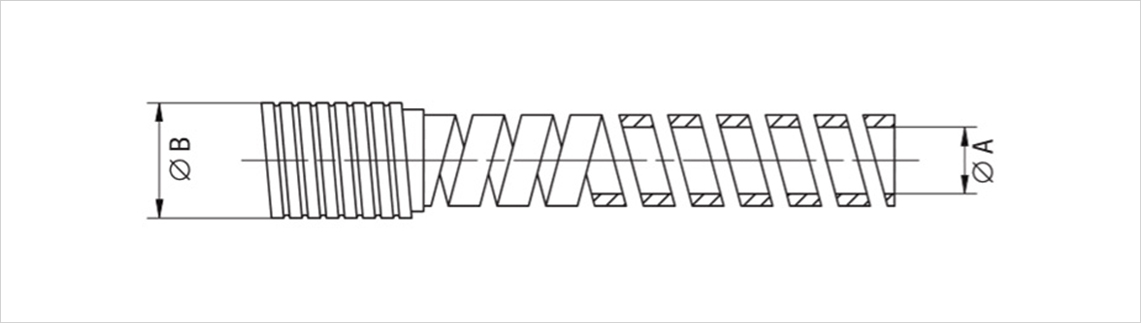

Shafts

Transmission and high-torque shafts

Transmission and high-torque shafts

For power transmission in the fields of machinery, aerospace and railway engineering, power tools, concrete vibrators, etc.

Construction

4 to 8 high-tensile wires per layer.

Applications

Power transmission in machinery, aerospace and railway engineering, power tools, concrete vibrators, etc.

Features

Very flexible, high rpm operation, quiet and low-vibration operation.

Downloads and Contact

Remote Control Shafts

Remote Control Shafts

For power seats and remote control of valves, machinery and dashboards in adverse environments.

Construction

4 to 12 high-tensile wires per layer

Applications

Power seats, remote control of valves, machinery, dashboards, etc. in adverse

environments.

Features

Low torsional deflection, bi-directional operation, high breakage load.

Downloads und Contact

Speedometer Shafts

Speedometer Shafts

For speedometers, counters or tachographs.

Construction

4 to 6 high-tensile wires per layer.

Applications

For powering speedometers, counters, tachographs, etc.

Features

High flexibility, low noise, low vibration.

Downloads und Contact

Stainless Steel Shafts

Stainless Steel Shafts

Chemical industry, food sector, nuclear engineering and medical technology.

Construction

4 to 12 high-tensile stainless steel wires per layer.

Applications

Chemical industry, food sector, nuclear engineering and medical technology.

Features

Very flexible, high rpm, shock absorption, smooth operation and low in vibration.

Downloads and Contact

Noise-critical Shafts

SU-Flock Shafts

Designed for applications in which noise is a critical factor, such as luxury car power seats, as well as in other fields in which low friction and noise are of critical importance.

Applications

For example in luxury car power seats

Features

Designed for noise-critical applications, operation in clockwise and counterclockwise direction, high loads.

Downloads and Contact

Shafts for Linear Movement

SU-Flex Shafts

For linear movement, such as sliding sunroof mechanisms in cars as well as for industrial applications.

Applications

Suitable for linear movement such as power windows and sliding sun roof mechanisms.

Features

Ideal for linear movement; the flocked design is especially suited for applications in which low noise is of critical importance.

Downloads and Contact

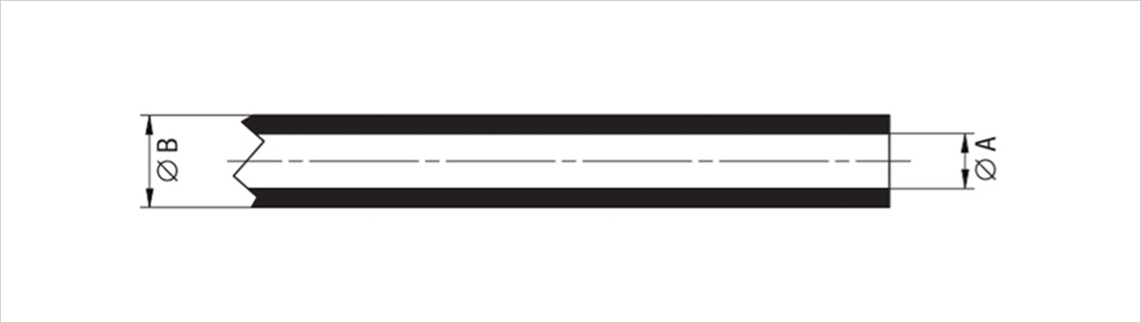

Hollow Shafts

Hollow Shafts

Orthopedic instruments, transmission of rotary motion with simultaneous transmission of electric/optical signals through the hollow part.

Construction

4 to 12 high-tensile wires per layer.

Applications

Orthopedic instruments, transmission of rotary motion with simultaneous transmission of electric/optical signals through the hollow part.

Features

Hollow shaft core, smooth running, very flexible.

Downloads and Contact

Complete Shafts

Complete SSB Shaft Assemblies with Plain Bearings

Standard shafts for industrial applications.

Construction

Includes shaft core with identical couplings on both ends and plastic or rubber casing. Coupling: cylindrical bore with locking screw, additional keyway for types –15/–20.

Applications

Standard shafts as complete sets for industrial applications.

Features

Robust design for continuous use.

Downloads and Contact

Complete SSB Shaft Assemblies with Ball Bearings

Standard shafts for industrial applications.

Construction

Includes shaft core with identical couplings on both ends and plastic or rubber casing. Coupling: cylindrical bore with locking screw, additional keyway for types –15/–20.

Applications

Standard shafts as complete sets for industrial applications.

Features

Robust design for continuous use.

Downloads and Contact

Complete NA Shaft Assemblies

For operation with Suhner flexible shaft motors and professional adjustment mechanisms.

Construction

Assembly includes shaft core with couplings, rubber casing with reinforcement boots and couplings.

Applications

For operation with Suhner flexible shaft motors and professional adjustment mechanisms.

Downloads and Contact

Manual Control Shafts

Manual Control Shafts

Complete standard shaft for professional adjusting mechanisms.

Construction

Includes shaft core with coupling (cylindrical bore with locking screw), plastic casing and hand wheel.

Applications

Complete standard shaft for professional adjusting mechanisms.

Downloads and Contact

Couplings

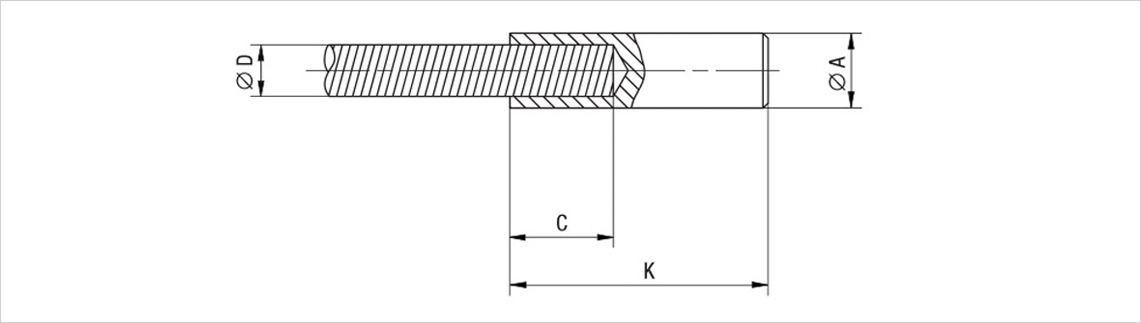

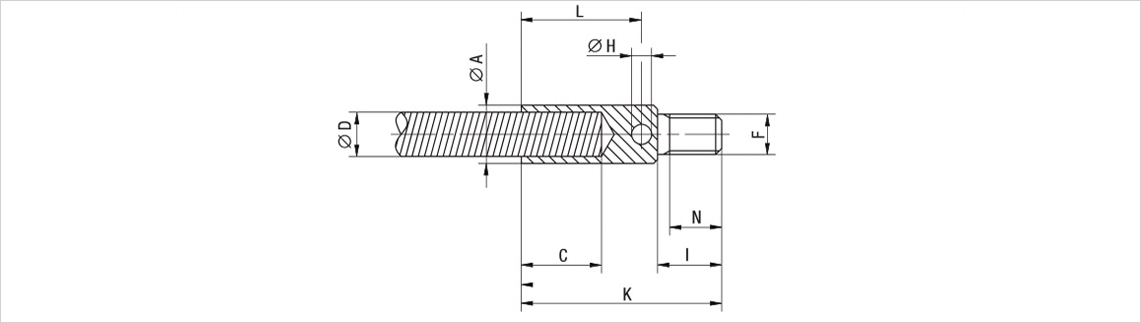

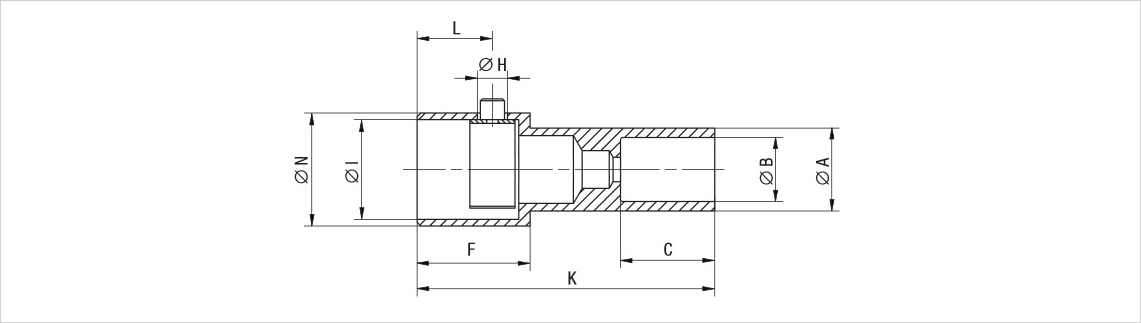

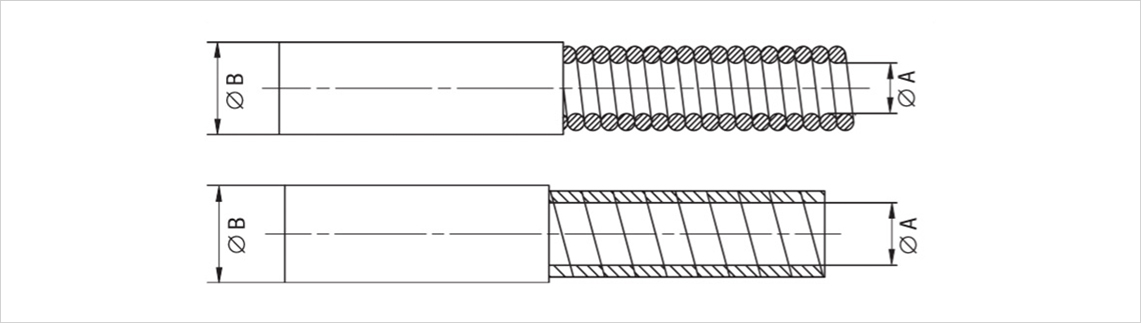

Cylindrical Shaft Coupling

Cylindrical Shaft Coupling

Cylindrical end connection

Construction

Cylindrical end connection, can be machined, crimped or soldered on.

About couplings

Wherever flexible shafts are used to solve the problem of rotary power transmission, a quick-release system should be considered for the purpose of easy assembly and replacement. Therefore the flexible rotating shaft and its casing are not mounted directly to the power source or driven components, but are connected via couplings of various kinds. As only the shaft is rotating, shaft and casing must be connected independently of each other. A complete connection system is thus required, usually consisting of a rotating shaft coupling and a casing coupling.

Types of flexible shaft couplings

Shaft couplings include both male and female types, which are secured or held in position by threads, locking screws, coupling surfaces, hexagonal surfaces or keyways. The simplest way of establishing a shaft coupling involves squaring off the end of the shaft itself, thus eliminating the cost of making and attaching additional couplings. For tools that must be changed frequently, quick-release couplings are available. For power drives in particular, one of the rotating shaft end couplings should be able to slide back and forth along the rotating part in order to accomodate relative changes in shaft length (due to flexing or variations in torsional load).

Downloads and Contact

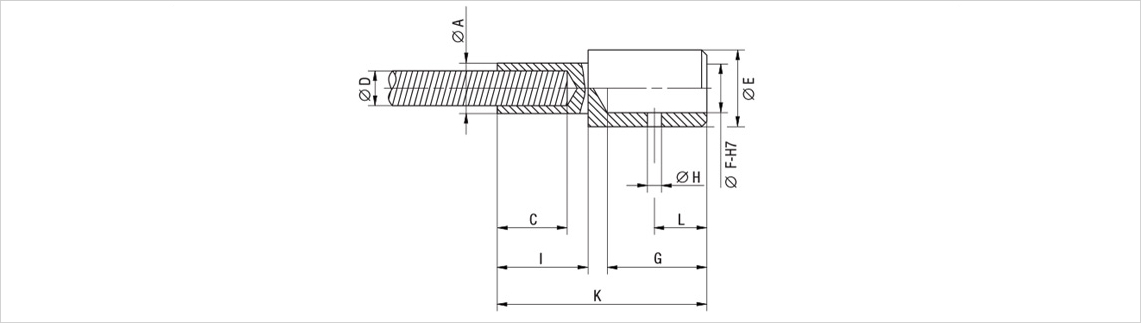

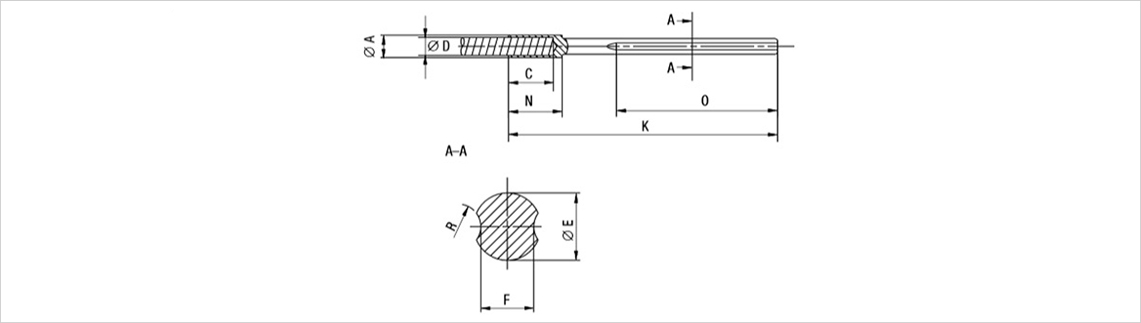

Sleeve Coupling

Sleeve Coupling

Cylindrical end connection with a central bore and a mounting bore

Construction

Cylindrical end connection with a central bore and a mounting bore, can be machined, crimped or soldered on.

About couplings

Wherever flexible shafts are used to solve the problem of rotary power transmission, a quick-release system should be considered for the purpose of easy assembly and replacement. Therefore the flexible rotating shaft and its casing are not mounted directly to the power source or driven components, but are connected via couplings of various kinds. As only the shaft is rotating, shaft and casing must be connected independently of each other. A complete connection system is thus required, usually consisting of a rotating shaft coupling and a casing coupling.

Types of flexible shaft couplings

Shaft couplings include both male and female types, which are secured or held in position by threads, locking screws, coupling surfaces, hexagonal surfaces or keyways. The simplest way of establishing a shaft coupling involves squaring off the end of the shaft itself, thus eliminating the cost of making and attaching additional couplings. For tools that must be changed frequently, quick-release couplings are available. For power drives in particular, one of the rotating shaft end couplings should be able to slide back and forth along the rotating part in order to accomodate relative changes in shaft length (due to flexing or variations in torsional load).

Downloads and Contact

DIN 42995 Coupling

DIN 42995 Coupling

Cylindrical end connection with metric internal thread

Construction

Cylindrical end connection with metric internal thread (in left-hand or right-hand direction), can be crimped or soldered on.

Suhner standard couplings

For connecting flexible shafts to machines and accessories.

Threaded connection according to DIN standard

Standard connection according to DIN 42995, with the shaft being connected by thread. Such connections are particularly suitable for heavy-duty conditions.

Downloads and Contact

Coupling (External Thread)

Coupling (External Thread)

End connection with metric external thread

Construction

End connection with metric external thread, with cross-bore, can be crimped or soldered on.

Applications

For connecting flexible shafts to machines and accessories.

Downloads and Contact

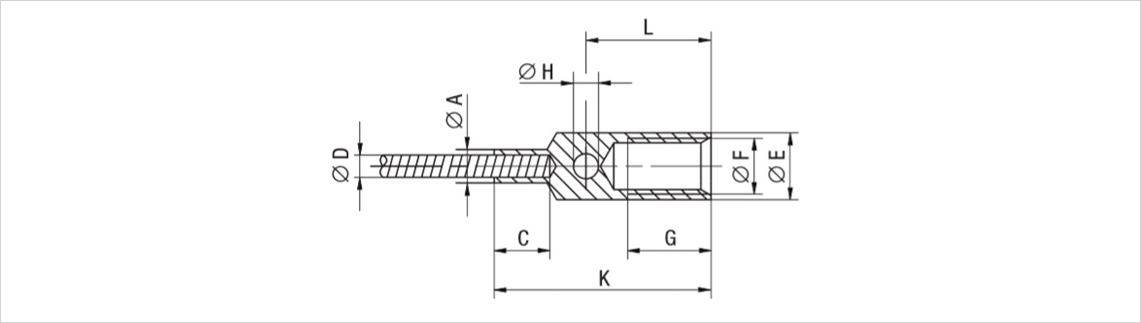

Type G Slip Coupling

Type G Slip Coupling

Patented quick-release coupling with automatic length adjustment

Construction

Patented quick-release coupling with automatic length adjustment, can be crimped or soldered on.

Applications

For connecting flexible shafts to machines and accessories.

The type G sliding connection

Operates in the form of a socket connection and allows for quick changing of the toolholders. Additionally, this connection permits the flexible shaft to slide along in the casing. Axial stresses, particularly when the flexible shaft is bent during operation, are thereby eliminated.

Downloads and Contact

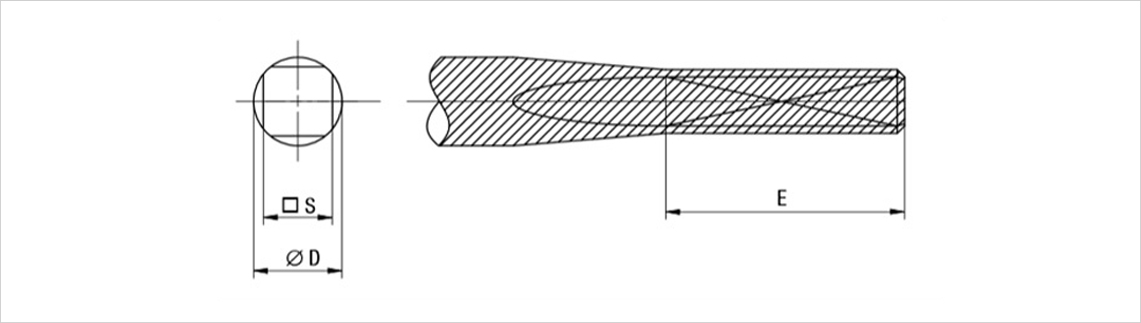

Square Ends

Square Ends

Simple end connection with floating length adjustment due to squared-off end design

Construction

Simple end connection with floating length adjustment due to squared-off end design.

Applications

For connecting flexible shafts to machines and accessories.

Downloads and Contact

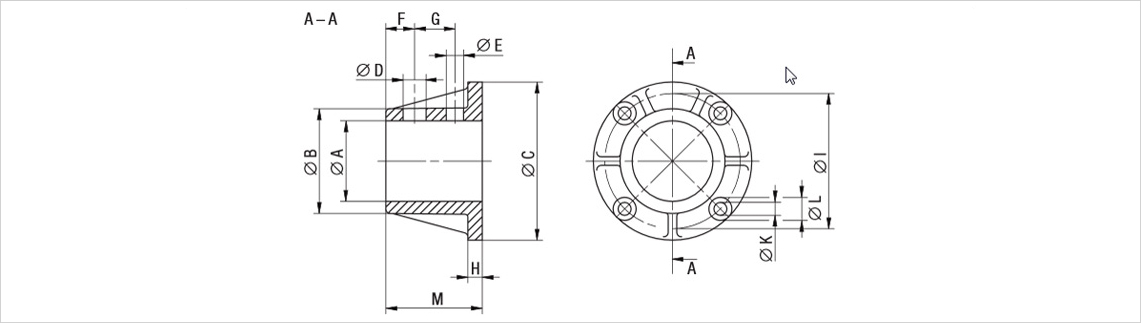

DIN 42995 Casing Flange

DIN 42995 Casing Flange

Permanently mountable hose flange

Construction

Permanently mountable hose flange. Suitable for casing couplings according to DIN 42995 with DIN 10 and 15 connections.

Application

Coupling connection for third-party machinery or accessories, quick change of hoses, with anti-twist protection, without twist keyway.

Downloads and Contact

DIN 42995 Casing Coupling

DIN 42995 Casing Coupling

Plug-in hose coupling with stop spring

Construction

Plug-in hose coupling with stop spring according to DIN 42995.

Suhner standard coupling

For frequent and quick changing of connections. Type G coupling designed for floating length adjustment on output side.

Downloads and Contact

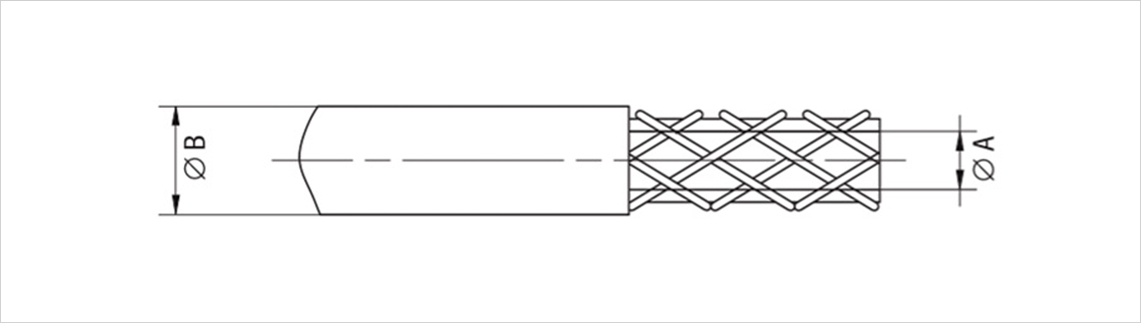

Casings

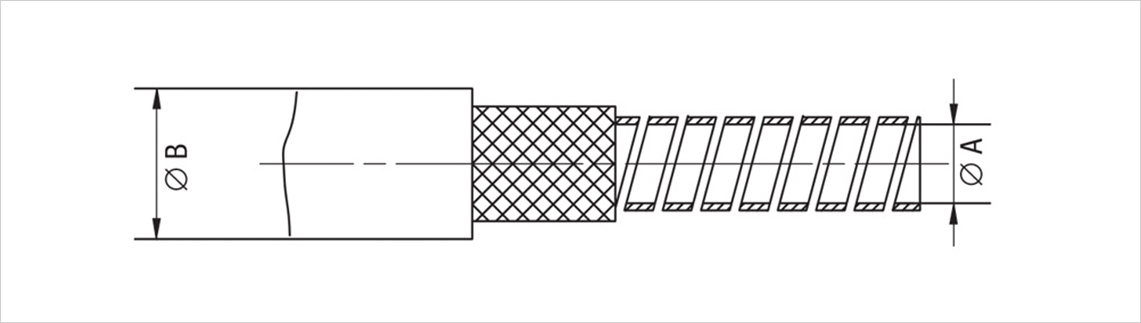

Type G Rubber Casing

Type G Rubber Casing

Construction

Flat steel spiral with textile mesh and two layers of neoprene. Grease and oil resistant.

Application

For power transmission during heavy-duty use of handheld power tools or machine tools.

Downloads and Contact

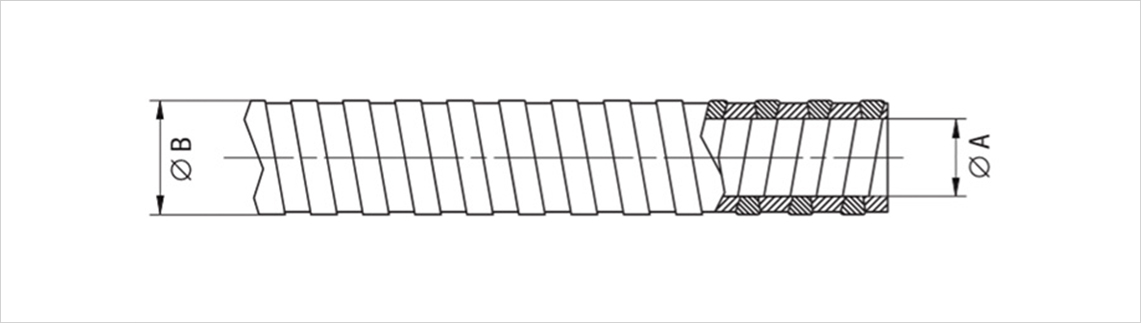

Type SE Metal Casing

Type SE Metal Casing

Construction

Bright finish, little flexibility, stays in desired bent position.

Application

Stationary installations, medium and light duty.

Downloads and Contact

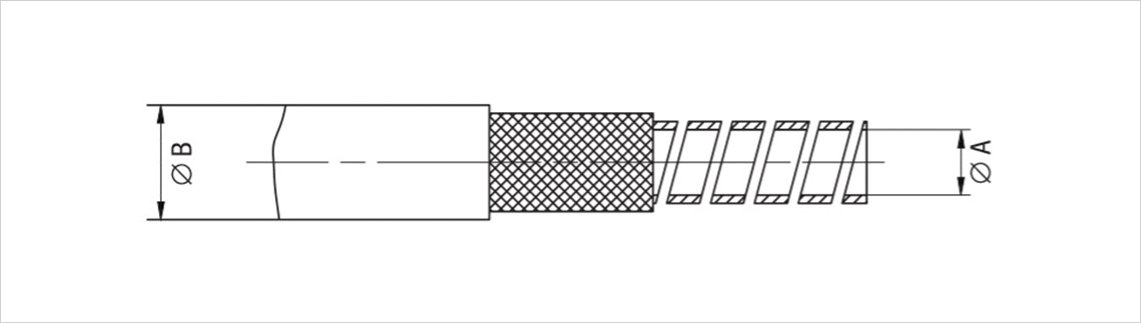

Type SEP Metal Casing

Type SEP Metal Casing

Construction

Similar to type SE metal casing, but with plastic cover, flexible.

Application

For mobile and stationary installations with high flexibility requirements.

Downloads and Contact

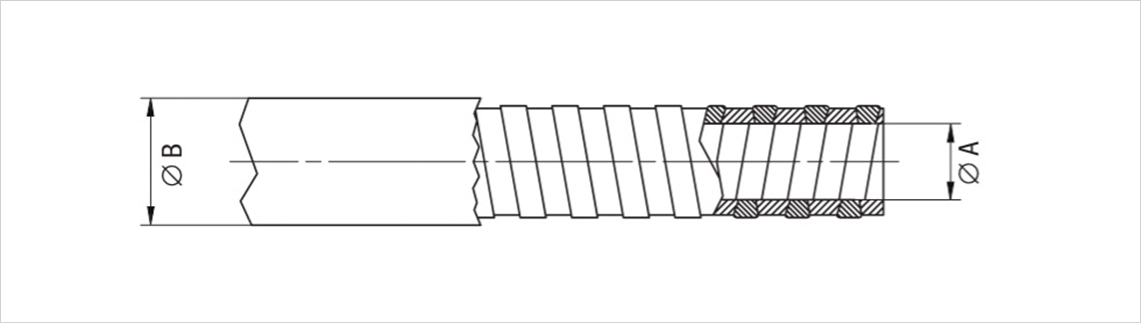

Type M Metal Casing

Type M Metal Casing

Construction

Flat steel spiral, galvanized flexible metal hose, sealed.

Application

Medium and heavy-duty use in stationary or changing locations. Also suitable for use at high temperatures.

Downloads and Contact

Type K Plastic Casing

Type K Plastic Casing

Materials

PB (polybutylene), PE (polyethylene), PA (polyamide).

Application

For simple applications.

Downloads and Contact

Type Ka Plastic Casing

Type Ka Plastic Casing

Construction

Plastic casing with inner tube made of polyamide and steel wire mesh, outer material: polybutylene.

Application

For applications at higher temperatures, stable in length.

Downloads and Contact

Type P Casing

Type P Casing

Construction

Flat steel spiral with steel mesh, encased in PVC.

Application

For light-duty applications where maximum flexibility is required.

Downloads and Contact

Type BR, BF, BRP, BFP Casings

Plastic-coated Type BR, BF, BRP, BFP Casings

Construction

Round steel or flat steel spiral, encased in PVC.

Application

For brake cables and light-duty applications.

Downloads and Contact

Follow us on